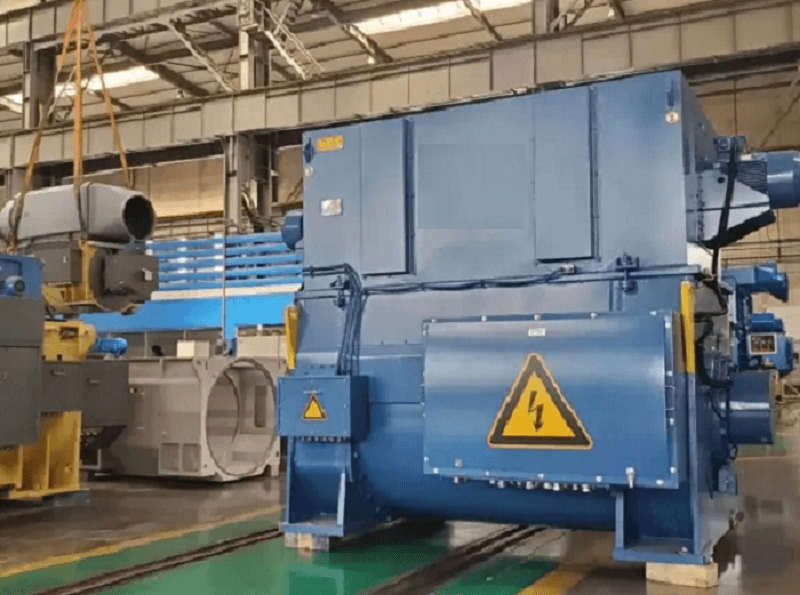

Squirrel cage asynchronous generator

Squirrel cage wind turbine generator is an induction generator with cage rotor structure, with power grade of 250KW to 5MW. It is used to support wind turbine generators with different power. The motor is installed in the engine room. The rotating shaft at the driving end is connected with the gearbox through the coupling to receive mechanical power, and the stator is connected with the power grid through the full power converter. The motor can operate within the speed range of 600 ~ 1800rpm to realize the conversion of mechanical energy into electrical energy. It has the characteristics of high efficiency, simple maintenance, high reliability and simple control. Because the air volume changes all the time, the squirrel cage can well stabilize the generator speed in torque control and deliver stable 50Hz AC of different powers to the power grid through stator.

1MW Squirrel cage asynchronous generator parameters

| type | 1MW | rated speed | 1550rpm |

| rated power | 2650kw | centre height | 630mm |

| rated Freqency | 51.4hz | rated voltage | 750v |

| pole | 4 | stator connection | delta |

| stator rated current | 2307A | power factor | 0.89 |

| efficiency | 97.2% | cooling method | air-air |

| insulation class | H | mounting type | IM1001 |

| protection IP | IP54 | Wight | 8300KG |

Main technical feature

Wound rotor doubly fed asynchronous generator

Doubly fed induction generator (DFIG) is a kind of wound rotor induction generator. It is not only the core component of variable speed constant frequency wind turbine, but also one of the key components of wind turbine localization. The generator is mainly composed of motor body and cooling system. The motor body is composed of stator, rotor and bearing system. The cooling system is divided into three structures: water cooling, air cooling and air cooling.

It is equipped with variable-speed doubly fed wind turbine generator sets with different power. The motor is installed in the engine room. The rotating shaft at the driving end is connected with the gearbox through the coupling to receive mechanical power. The stator is directly connected with the power grid. The rotor is connected with the power grid through four quadrant converter. The frequency, voltage and The amplitude and phase are automatically adjusted by the frequency converter according to the operation requirements. The unit can realize constant frequency power generation at different speeds to meet the requirements of power load and grid connection. Due to the use of AC excitation, the generator and power system form a "flexible connection", that is, the excitation current can be adjusted according to the grid voltage, current and generator speed, and the output current of the generator can be accurately adjusted to meet the requirements.

1.5MW-5MW Wound rotor doubly fed parameter table

| capacity model | 1.5MW | 2MW | 2.5MW | 3MW | 4MW | 5MW |

| rated power | 1560kw | 2150KW | 2600 | 3100-3750KW | 3600-4200KW | 5300KW |

| rated Freqency | 50hz | 50hz | 50hz | 50hz | 50hz | 50hz |

| pole | 4 | 4 | 6 | 4 | 6 | 6 |

| stator/rotor current | 1090/390A | 1506/590 | 1822/665A | |||

| efficiency | ≥97% | ≥97% | ≥97% | ≥97% | ≥97% | ≥97% |

| rotor voltage | 1990V | 1850V | 1990v | 1880V | 1850V | 2049V |

| insulation class | H | H | H | H | H | H |

| rated speed | 1800 | 1800 | 1200rpm/min | 700-1380rpm | 1200 | 1200 |

| centre height | 500 | 500 | 630 | 560 | 630 | 710 |

| stator/rotor voltage | 690/420V | 690/389V | 690/415V | 690/415 | 690 | 690 |

| stator connection | Δ/Y | Δ/Y | Δ/Y | Δ/Y | Y/Y | Y/Y |

| power factor | 0.95ind-1-0.95cap | 0.95ind-1-0,95cap | 0.95ind-1-0,95cap | 0.95ind-1-0,95cap | 0.95ind-1-0,95cap | 0.95ind-1-0,95cap |

| cooling method | air-air/ air-water | air-air/ air-water | air-air/ air-water | air-air/ air-water | air-air/ air-water | air-air/ air-water |

| mounting type | IM1001 | IM1001 | IM1001 | IM1001 | IM1001 | IM1001 |

| protection IP | IP23/IP54 | IP23/IP54 | IP23/IP54 | IP23/IP54 | IP23/IP54 | IP23/IP54 |

| weight | 7200KG | 7800KG | 11300KG | 12500KG | 13200KG | 17600 |

Main technical feature

3MW Permanent magnet synchronous generator

The motor is a 3MW integrated semi direct drive permanent magnet wind turbine, which is matched with 3MW permanent magnet wind turbine and is suitable for inland and coastal wind farms. The motor is installed in the engine room and driven by impeller and speed increasing box. The stator is connected to the power grid through four quadrant converter to convert mechanical energy into electrical energy.

The generator is directly suspended and connected with the gearbox, and shares some parts such as bearings, which greatly shortens the axial size of the unit. The stator casing water-cooling structure and forced air cooling of the rotor are adopted to further reduce the volume and weight of the motor. By adding a primary gearbox at one end of the generator for speed increase, it not only reduces the failure risk and loss of the high-speed gearbox of the doubly fed wind turbine generator, but also avoids the difficulties in manufacturing, transportation and maintenance and the increase in cost caused by the excessive volume and weight of the generator of the low-speed unit. It has the advantages of simplicity, reliability and simple and effective solutions for low-voltage ride through.

Permanent magnet synchronous generator parameter table

| type | 3MW | rated speed | 480/526/550rpm |

| rated power | 3200/3400/3620KW | centre height | 630mm |

| rated Freqency | 45.8hz | rated voltage | 710v |

| pole | 10 | stator connection | Y |

| stator rated current | power factor | 0.9 cap | |

| efficiency | 97.2% | cooling method | air-water |

| insulation class | F/H | mounting type | IM1001 |

| protection IP | IP54 | Wight | 12000KG |

Main technical feature

The generator is suspended and connected with the gearbox, integrates the rear bearing of the gearbox and the bearing at the driving end of the generator, shares the front cover and lubrication system of the generator, cancels the coupling, greatly shortens the axial size of the transmission chain, and reduces the weight and cost of the whole machine;

The rotor magnetic pole adopts the eccentric magnetic pole box structure, the harmonic content of air gap magnetic field is low, and the assembly and protection of permanent magnet are simple and reliable;

The stator winding of generator adopts casing water cooling, and the waterway adopts "s" double circuit heat exchange flowing in the opposite direction, with uniform heat dissipation; The rotor adopts forced air cooling to isolate the thermal influence of the stator on the permanent magnet;

The stator adopts inclined slot structure to effectively weaken tooth harmonic;

Insulated end caps are used to prevent damage to bearings caused by shaft current.

please confirm details with Elom sales team befor order.